Cumulative Flow Diagram Cycle Time, A Client Reports Back On Progress One Year After A Professional Scrum With Kanban Workshop Scrum Org A Client Reports Back On Progress One Year After A Professional Scrum With Kanban Workshop

- Cumulative Flow Diagram 35

- Cumulative Flow Diagram Cfd Agile Development Project Management Scrum Methodology Bug Tracker And Team Collaboration Yodiz

- Tracking Projects Based On Agile Methodology Itm Platform

- Kanban Analytics Metrics Lead And Cycle Time And Cumulative Flow Diagram Kanban Tool

- Cumulative Flow Diagram What Is It And How To Read

- Cumulative Flow Diagram What Is It And How To Read

- Cumulative Flow Diagram For Best Process Stability

- What Is A Cumulative Flow Diagram Acm

- 4 Key Flow Metrics And How To Use Them In Scrum S Events Agilesparks

- Visualize Your Workflow With The Cumulative Flow Diagram Nutcache

Find, Read, And Discover Cumulative Flow Diagram Cycle Time, Such Us:

- Figure 2 From Product Evaluation Through Contractor And In House Metrics Semantic Scholar

- Cumulative Flow Diagram

- Better Projects Cumulative Flow And Requirements Traceability

- Mindsettlers Cumulative Flow Diagrams

- Professional Scrum With Kanban Don T Just Limit Wip Optimize It Post 2 Of 3 Professional Scrum With Kanban Don T Just Limit Wip Optimize It Post 2 Of 3 Scrum Org Psk

If you re searching for 1998 Kenworth W900 Fuse Box Diagram you've arrived at the ideal place. We have 104 graphics about 1998 kenworth w900 fuse box diagram adding images, pictures, photos, wallpapers, and much more. In such webpage, we also provide variety of images out there. Such as png, jpg, animated gifs, pic art, symbol, black and white, translucent, etc.

You use cumulative flow diagrams cfd to monitor the flow of work through a system.

1998 kenworth w900 fuse box diagram. Work in progress wip. Today i want to share something successful teams do to improve their process and get more work done delivering projects on time and making their clients and bosses happier. The progress of this line also serves as the burnup graph of the entire process.

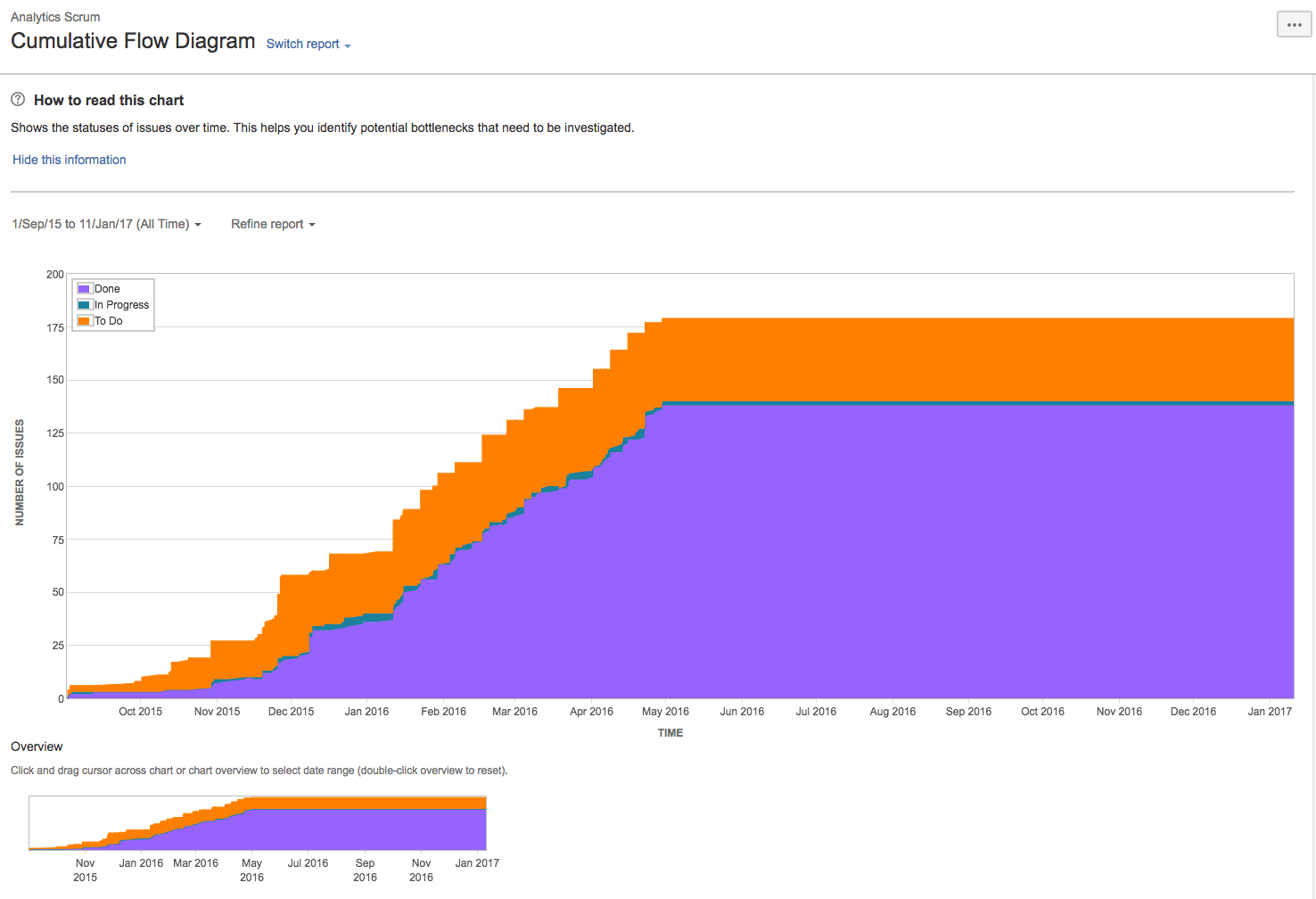

On september 5 2016. The graph is built from different colored bands of tasks gathered in various columns. The start point of your project is to the left of the graph while the end point is towards the right.

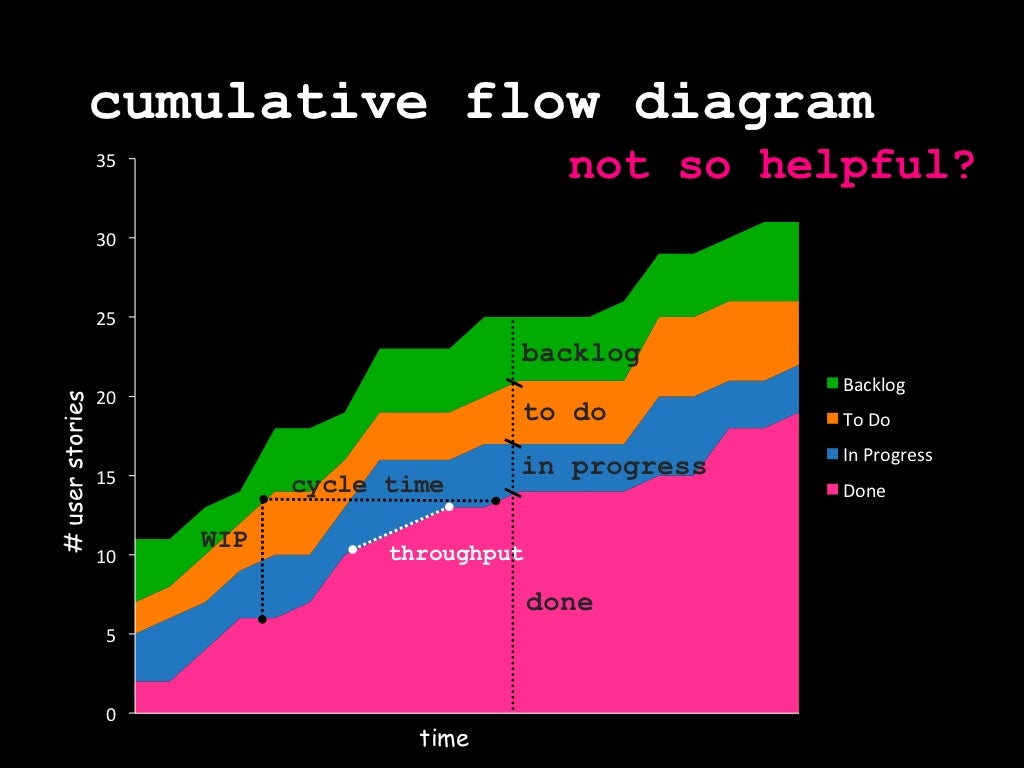

The cumulative flow diagram aims to show the stability of your process over time. The cfd is a time based plot of the cards as they move from the left to the right on a kanban board. Cycle time points to the time a work item takes to go through part of the processfor example doing development and testing.

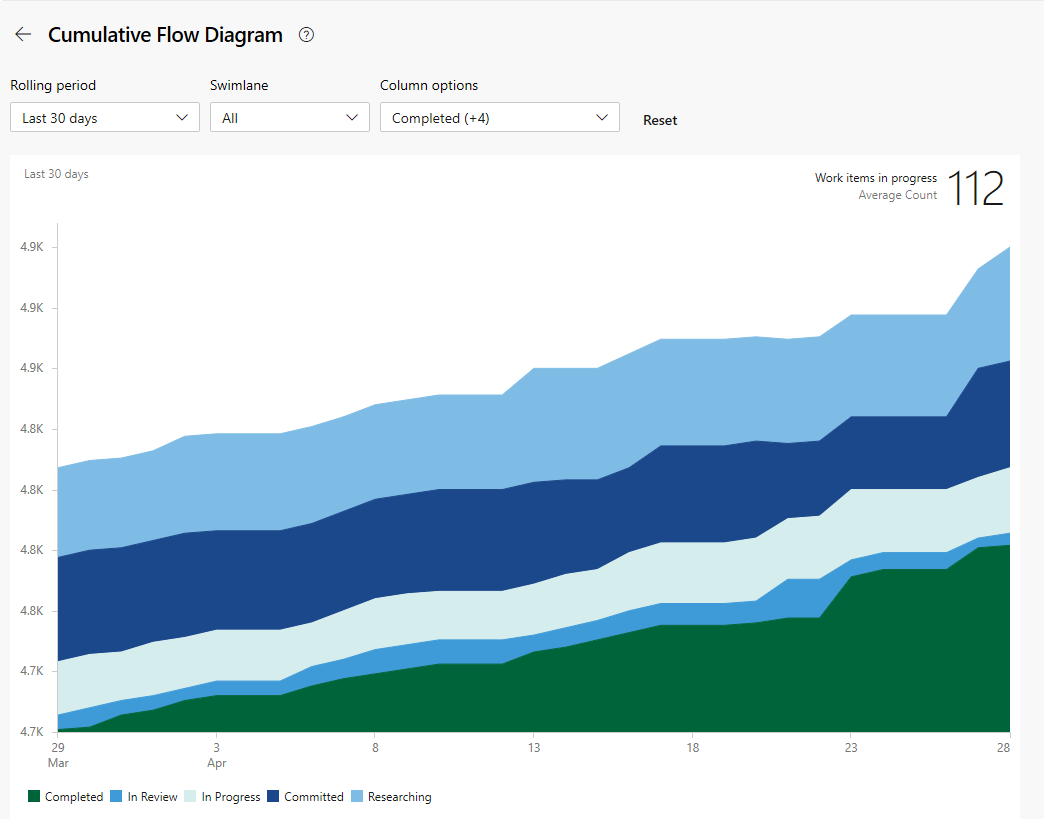

What is a cumulative flow diagram. The cumulative flow diagram visualises how tasks mount up over time together with their distribution along the process stages. The lowermost line indicates the number of items in the completed state at any point in time.

Cfds are simple stacked area charts that show the number of tasks in each column of the kanban. The cumulative flow diagram also known as cfd is one of the most advanced kanban and agile analytics charts. To configure or view cfd charts see configure a cumulative flow chart.

Time frame x axis the cumulative flow diagram also highlights your project time frame along the x axis. Or you can add the lead time and cycle time control charts to your dashboards. It tracks and accumulates each task that has ever entered or progressed to any stage of your workflow.

This axis is useful as itll help you chart your project progress across each sprint and identify if any issues occurred. In the graph the cycle time for parts of the process measures the horizontal difference between the top and bottom lines at any point along the cdf. The two primary metrics to track cycle time and lead time can be extracted from the chart.

Using the diagram you can get an idea of how your work in progress throughput and cycle time change over time. What is a cumulative flow diagram cfd. It provides a concise visualization of the three most important metrics of your flow.

Using cycle time and a cumulative flow diagram to get more work done by eliminating the bottlenecks in your process.

Figure 2 From Product Evaluation Through Contractor And In House Metrics Semantic Scholar 1998 Kenworth W900 Fuse Box Diagram

1998 Kenworth W900 Fuse Box Diagram, Introducing Our First Kanban Report For Next Gen Projects Cumulative Flow Diagram

- Kanban In Practice Ppt Video Online Download

- Cumulative Flow Diagram Kanbanize Knowledge Base

- Cumulative Flow Diagram For Best Process Stability

1998 Kenworth W900 Fuse Box Diagram, How To Read The Cumulative Flow Diagram Infographic Nave

- Cumulative Flow Diagram Nave

- What Is A Cumulative Flow Diagram Cfd The Corrello Blog

- Agile Metrics What To Measure And Why

1998 Kenworth W900 Fuse Box Diagram, Cumulative Flow Diagram Throughput I M Wright S Hard Code

- Cumulative Flow Diagram Kanban In 30 Days

- Cumulative Flow Diagram

- What Is Kanban Cards Boards Methodology Explained

More From 1998 Kenworth W900 Fuse Box Diagram

- Plot Diagram For A Sound Of Thunder

- Car Trailer Plug Diagram

- Bc547 Amplifier Circuit Diagram

- Workflow Charts

- Venn Diagram Rstudio

Incoming Search Terms:

- Cumulative Flow Diagram Kanban Work In Process Lead Time Map Map Elevation Urban Design Png Pngwing Venn Diagram Rstudio,

- How To Create A Cumulative Flow Diagram Cfd In Excel Modern Kanban Venn Diagram Rstudio,

- Introducing Our First Kanban Report For Next Gen Projects Cumulative Flow Diagram Venn Diagram Rstudio,

- Kanban Metrics Improve Service Delivery With Metrics Aktiasolutions Venn Diagram Rstudio,

- Using Cycle Time And A Cumulative Flow Diagram To Get More Work Done By Eliminating The Bottlenecks In Your Process The Corrello Blog Venn Diagram Rstudio,

- Mindsettlers Cumulative Flow Diagrams Venn Diagram Rstudio,